SEAWEED CULTIVATION

A. Background

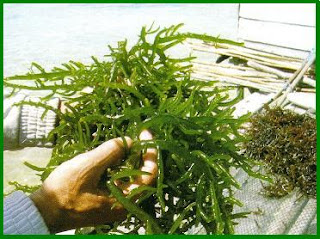

A. BackgroundSeaweed (sea Weeds) who in the world of science known as Algae is very popular in the commercial world end - the end of this.

Seaweed was first known by Chinese people think - about the year 2700 BC. At that time the seaweed is widely used for vegetable and drugs - drugs. In the year 65 BC, the Romans use it as a cosmetic raw material. But with the development time, knowledge about the grass growing lautpun. Spain, France, and England made the seaweed as raw material for making glass.

When the utilization of seaweeds in Indonesia is not known. Only when the Portuguese came to Indonesia around 1292 years, seaweed has been used as vegetables. Only in the period before World War - 2, noted that Indonesia has been exporting to the United States seaweed, Danish, and French.

Now this seaweed in Indonesia, many developed on the coast of Bali and Nusa Tenggara. Given the length of the coastline of Indonesia (81,000 km), the opportunity is very promising for seaweed cultivation. If you view the market demand for the world to Indonesia every year - average 21.8% of the world needs now is the fulfillment to supply the demand is still very low, ie only around 13.1%. The low supply from Indonesia due to unfavorable farming activities and the lack of information about the potential of seaweed to farmers.

B. Contents

Seaweed is commonly used is the type of red algae (Rhodophyceae) because it contains so - so, keraginan, porpiran, or pigment furcelaran fikobilin (consisting of fikoeretrin and fikosianin) which is a provision for foods that contain lots of carbohydrates. But there is also the advantage of brown algae (Phaeophyceae). Brown algae contains many pigments chlorophyll a and c, beta carotene, and fukosantin violasantin, pirenoid, and sheets of photosynthesis (filakoid). Besides the brown algae also contain food reserves in the form of Laminarin, cellulose, and algin. In addition to the material - the material, red and brown algae contain many jodium.

C. Benefit

1. Agar - agar

Society in general knows that - so in the form of flour normally used for making pudding. But people do not know exactly what order - in order for it. Agar - agar is a meruapakan sulfanik acid esters of linear and galakto obtained by extracting the algae species Agarophytae. Order - order is soluble in hot water in nature and does not dissolve in cold water.

Now is the use of so - so the more developed, which used just for food alone is currently being used in textiles, cosmetics, and others - others. Its main function is as pemantap materials, and author of the emulsion, thickening, filler, and gel-making materials. In the industry, so - so widely used in industry for the manufacture of foods such as breads, soups, sauces, ice cream, jelly, candy, sherbet, cheese, pudding, jam, beer, wine, coffee, and chocolate. In the pharmaceutical industry is useful as a laxative or laxative, wrapping the capsule, and mix ingredients printer tooth samples. In the textile industry can be used to protect the sheen of silk. In the cosmetics industry, in order - so useful in the manufacture of ointments, creams, lotions, lipstick and soap. In addition there are many other benefits from the agar - agar, as for the manufacture of film plates, toothpaste, shoe polish, paper, and canning of fish and meat.

2. Keraginan

Keraginan is a polysaccharide compound composed of units of D-galactose and L-galactose 3.6 anhidrogalaktosa linked by ties 1-4 glikosilik. Cash characteristics of each unit is keraginan galaktosanya sulfate binding clusters, the number sulfatnya approximately 35.1%.

Keraginan almost the same functionality in order - in order to, among others, as a stabilizer, thickener, gel-forming, and pengemulsi. Keraginan widely used in food industry for making cakes, bread, makroni, jam, jelly, juice, beer, ice cream, and gel coatings of meat products. In the pharmaceutical industry widely used for toothpaste and drugs - drugs. But they can also be used in textiles, cosmetics and paints.

3. Algin (Alginate)

Algin is derived from brown seaweed algae species. This is a polymer of algin uronat acids that are arranged in the form of long linear chains. Form of algin on the market are often found in the form of starch sodium, potassium or ammonium alginate is soluble in water.

Algin usability in the industry is as a thickening, stabilizer, pengemulsi, and forming a thin layer of oil-resistant. Algin used in many industries in the food industry for the manufacture of ice cream, sherbet, ice milk, bread, cakes, sweets, butter, sauces, meat canning, jam, syrup and pudding. In the pharmaceutical industry widely used for the tablets, ointments, capsules, patches, and filters. Cosmetic industry for the cream, lotion, shampoo, hair dye,. And in other industries such as textiles, paper, photography, insecticides, pesticides, and wood preservatives.

D. TON function in Seaweed Ecology

Seaweed was first found living in nature rather than the result of cultivation. They were scattered in the waters in accordance with environmental needs. Seaweed stuck to need a place to support life. In the wild where it can be attached to dead coral, shells of molluscs, and may also be sand and mud.

Also in dire need of seaweed sunlight to establish the process of photosynthesis. Number of sunlight is strongly influenced by the brightness of the sea water. So that needs sunlight available in an optimal amount of depth in it shall be governed cultivate them. Depth is ideally located 30-50 cm from the surface of the water.

Seaweed photosynthesis process is not only influenced by sunlight, but also require nutrients in sufficient quantities both macro and micro. These nutrients obtained from the environment much water is absorbed directly by all parts of the plant. To supply this nutrient fertilization is usually done during cultivation. To help provide nutrients in optimal quantities and so quickly absorbed by the seaweed, it must be provided with nutrients that have been in a state ready for use (ionic). These nutrients contained in many TON (Pond Organic Nusantara).

TON (Pond Organic Nusantara), containing all the materials required for the growth of seaweed. Both provide a complete micro nutrients, also provides a macro element. TON addition will also improve the quality of seaweed, because it will reduce the pollution level of heavy metals which will also be absorbed by the seaweed. If heavy metals are not binding, it will come absorbed in the absorption process of nutrients from the seaweed, making it very dangerous for consumers. Given TON, heavy metals will be bound in the form of compounds and will be difficult to settle or be absorbed by the absorption process.

Seaweed growth is also influenced by the amount of dissolved oxygen (DO), salinity (salt content) and temperature. Oxygen content in addition affected by water movement is also influenced by the availability of nutrients. TON also so very important to support the availability of oxygen in the water. Ideal temperature for growth of seaweed in the range 200-280 C

With the availability of nutrients in the number of optimal and balanced environmental conditions because of the influence of TON, the quality and quantity of material - material that is contained by the sea grass will also increase.

In addition, the use of TON for seaweed farming will also help to bind compounds - compounds and elements - hazardous substances in the waters. Compounds - compounds and elements of this if adsorbs in metabolism system of seaweed, will disrupt the growth of seaweed and also will decrease the quality of the results. Additionally if the seaweed is to be used for food, would be very dangerous for the menkonsumsinya. The content of active carbon compounds from the TON will greatly help to reduce the compounds and elements - such hazardous substances.

E. Seaweed Cultivation and How to Use TON (Pond Organic Nusantara)

In carrying out the cultivation of seaweed, the first to be considered is the selection of the location of cultivation. Better farming area that is not cultivated in the waters of fluctuating salinity (salt content), a large and free from industrial and household pollution. Besides the choice of location should also consider the economic and labor aspects.

Seaweed farming can be done at an area off the coast and in the ponds. In the present discussion we will emphasize on cultivation in ponds. This is considering the role TON ineffective if waters off the (beach). For the cultivation of the waters off distinguishable in several methods, namely:

1. Remove Method Association

Where this is done by tying seaweed seedlings on a string - the string that was set in a row - row in the territorial waters of the sea with a depth of 30-60 cm. Seaweed is planted in the bottom waters.

2. Raft Methods

This method is done in waters more than 60 cm depth. Working with grass seed in the rope binding - a rope tied around the peg - peg in a position like floating in the middle - the middle depth of water.

3. Hanging rope method

If the two methods over the position of seeds - seeds of seaweed in a horizontal position (flat), then the method is performed with a noose tied the seeds - seeds of seaweed in a vertical position (perpendicular) on the ropes - the rope is arranged in rows.

Use TON with three ways above can only be done by soaking seed system. Because if TON applied in the waters would not be effective and many are lost by the ocean currents. Seed soaking method is done by:

1. TON dissolve in seawater is placed in the container.

2. To one liter of sea water given quarter tablespoons (50-10 grams) TON and add 1-2 cc Hormonik.

3. Soak for 4-5 hours, and seed planting.

TON usage will be very effective if applied in the cultivation of seaweed in ponds. How to cultivation in ponds can be done with dispersive methods. The trick is as follows:

1. Ponds should be equipped with a channel revenues and expenditures.

2. Dried pond first.

3. Sprinkle the lime to neutral pH (0.5 - 2 tons per hectare depending on the acidity conditions of land).

4. Leave it for a week.

5. Apply TON, with a dose of 1-5 bottles per-hectare (for regions - areas of high pollution levels, the dose is raised), by dissolving it with water first, then spread evenly in the bottom of ponds.

6. Leave it a day

7. Add water to a height of 70 cm.

8. Sprinkle sea grass seed that has been soaked with TON and hormonik such as by soaking the above. With a density of 80-100 g/m2.

9. When the pond bottom hard enough, the seeds can be plugged in like planting rice.

10. Not need added fertilizer macro.

F. Maintenance and application of TON (Pond Organic Nusantara) aftershocks.

During cultivation, the supervision must be carried out continuously. Especially for cultivation in ponds must dilakukaan least 1-2 weeks after stocking of seedlings, this is to control the position of the spread of seaweed. Usually because of the influence of wind, the seeds will collect in certain areas, if so should be separated and spread out evenly again in the pond area.

Water in the form of dust dirt (mud dissolved / suspended solid) is often attached to plants, especially on calm waters such as ponds. At that time, the plants are staggered - dangle in the water so that plants are always clean from dirt. This dirt will interfere with the metabolism of seaweed. Some marine plants such as Ulva, Hypea, Chaetomorpha and Enteromorpha plants often convolute. Plants - plants should be immediately removed and separated from seaweed in order not to degrade the quality of results. You do this by collecting it on the ground. Sea urchins, fish and turtles are herbivorous animals that must be prevented in order not to prey on sea grass. To avoid that is usually installed around the net cultivated area. For cultivation in ponds is done by placing nets in channel revenues and expenditures.

G. Harvesting

At this stage of harvesting must be considered an appropriate way and time to obtain results in accordance with market demand in quality and quantity.

Plants can be harvested after the age of 6-8 weeks after planting. How to harvest is to lift the entire plant seaweed ashore. Seaweed is farmed in ponds, harvested by plants raised and bred to be left a little further. Or it could be done by separating the strings with a branch - a branch of its parent plants, but this way will result in the obtainment little keraginan and growth for the cultivation of mother plants will decline further.

If the seaweed is harvested at the age of about a month, usually obtained by the weight ratio of wet and dry weight of 8: 1, and if harvested at the age of two months will usually be obtained the ratio 6: 1. For Gracilaria species are usually obtained yields approximately 1500 - 2000 kg of dry seaweed per-hectare. Hopefully, with the use of TON (Pond Organic Nusantara) will increase by approximately 30-100%.

No comments:

Post a Comment